Contains Nonbinding Recommendations

Draft – Not for Implementation

Computer Software Assurance for

Production and Quality System

Software

______________________________________________________________________________

Draft Guidance for Industry and

Food and Drug Administration Staff

DRAFT GUIDANCE

This draft guidance document is being distributed for comment purposes

only.

Document issued on September 13, 2022.

You should submit comments and suggestions regarding this draft document within 60 days of

publication in the Federal Register of the notice announcing the availability of the draft

guidance. Submit electronic comments to https://www.regulations.gov. Submit written

comments to the Dockets Management Staff, Food and Drug Administration, 5630 Fishers Lane,

Room 1061, (HFA-305), Rockville, MD 20852. Identify all comments with the docket number

listed in the notice of availability that publishes in the Federal Register.

For questions about this document regarding CDRH-regulated devices, contact the Compliance

and Quality Staff at 301-796-5577 or by email at [email protected]. For questions

about this document regarding CBER-regulated devices, contact the Office of Communication,

Outreach, and Development (OCOD) at 1-800-835-4709 or 240-402-8010, or by email at

U.S. Department of Health and Human Services

Food and Drug Administration

Center for Devices and Radiological Health

Center for Biologics Evaluation and Research

Contains Nonbinding Recommendations

Draft – Not for Implementation

Preface

Additional Copies

CDRH

Additional copies are available from the Internet. You may also send an email request to CDRH-

[email protected] to receive a copy of the guidance. Please include the document number

17045 and complete title of the guidance in the request.

CBER

Additional copies are available from the Center for Biologics Evaluation and Research (CBER),

Office of Communication, Outreach, and Development (OCOD), 10903 New Hampshire Ave.,

Bldg. 71, Room 3128, Silver Spring, MD 20993-0002, or by calling 1-800-835-4709 or 240-402-

biologics/guidance-compliance-regulatory-information-biologics/biologics-guidances.

Contains Nonbinding Recommendations

Draft – Not for Implementation

Table of Contents

I. Introduction .......................................................................................................................................................... 4

II. Background .......................................................................................................................................................... 5

III. Scope .................................................................................................................................................................... 6

IV. Computer Software Assurance ............................................................................................................................. 6

V. Computer Software Assurance Risk Framework ................................................................................................. 7

Identifying the Intended Use........................................................................................................................7

Determining the Risk-Based Approach........................................................................................................9

Determining the Appropriate Assurance Activities ...................................................................................13

Establishing the Appropriate Record .........................................................................................................16

Appendix A. Examples ................................................................................................................................................ 20

Example 1: Nonconformance Management System ............................................................................................... 20

Example 2: Learning Management System (LMS) ................................................................................................ 23

Example 3: Business Intelligence Applications ...................................................................................................... 24

Contains Nonbinding Recommendations

Draft – Not for Implementation

4

Computer Software Assurance for

1

Production and Quality System

2

Software

3

______________________________________________________________________________

4

Draft Guidance for Industry and

5

Food and Drug Administration Staff

6

7

This draft guidance, when finalized, will represent the current thinking of the Food and Drug

8

Administration (FDA or Agency) on this topic. It does not establish any rights for any person

9

and is not binding on FDA or the public. You can use an alternative approach if it satisfies

10

the requirements of the applicable statutes and regulations. To discuss an alternative

11

approach, contact the FDA staff or Office responsible for this guidance as listed on the title

12

page.

13

14

I. Introduction

1

15

FDA is issuing this draft guidance to provide recommendations on computer software assurance

16

for computers and automated data processing systems used as part of medical device production

17

or the quality system. This draft guidance is intended to:

18

19

· Describe “computer software assurance” as a risk-based approach to establish confidence

20

in the automation used for production or quality systems, and identify where additional

21

rigor may be appropriate; and

22

23

· Describe various methods and testing activities that may be applied to establish computer

24

software assurance and provide objective evidence to fulfill regulatory requirements,

25

such as computer software validation requirements in 21 CFR part 820 (Part 820).

26

27

When final, this guidance will supplement FDA’s guidance, “General Principles of Software

28

Validation” (“Software Validation guidance”)

2

except this guidance will supersede Section 6

29

(“Validation of Automated Process Equipment and Quality System Software”) of the Software

30

Validation guidance.

31

32

1

This guidance has been prepared by the Center for Devices and Radiological Health (CDRH) and the Center for

Biologics Evaluation and Research (CBER) in consultation with the Center for Drug Evaluation and Research

(CDER), Office of Combination Products (OCP), and Office of Regulatory Affairs (ORA).

2

Available at https://www.fda.gov/regulatory-information/search-fda-guidance-documents/general-principles-

software-validation.

Contains Nonbinding Recommendations

Draft – Not for Implementation

5

For the current edition of the FDA-recognized consensus standard referenced in this document,

33

see the FDA Recognized Consensus Standards Database.

3

34

35

In general, FDA’s guidance documents do not establish legally enforceable responsibilities.

36

Instead, guidances describe the Agency’s current thinking on a topic and should be viewed only

37

as recommendations, unless specific regulatory or statutory requirements are cited. The use of

38

the word should in Agency guidances means that something is suggested or recommended, but

39

not required.

40

41

II. Background

42

FDA envisions a future state where the medical device ecosystem is inherently focused on device

43

features and manufacturing practices that promote product quality and patient safety. FDA has

44

sought to identify and promote successful manufacturing practices and help device

45

manufacturers raise their manufacturing quality level. In doing so, one goal is to help

46

manufacturers produce high-quality medical devices that align with the laws and regulations

47

implemented by FDA. Compliance with the Quality System regulation, Part 820, is required for

48

manufacturers of finished medical devices to the extent they engage in operations to which Part

49

820 applies. The Quality System regulation includes requirements for medical device

50

manufacturers to develop, conduct, control, and monitor production processes to ensure that a

51

device conforms to its specifications (21 CFR 820.70, Production and Process Controls),

52

including requirements for manufacturers to validate computer software used as part of

53

production or the quality system for its intended use (see 21 CFR 820.70(i)).

4

Recommending

54

best practices should promote product quality and patient safety, and correlate to higher-quality

55

outcomes. This draft guidance addresses practices relating to computers and automated data

56

processing systems used as part of production or the quality system.

57

58

In recent years, advances in manufacturing technologies, including the adoption of automation,

59

robotics, simulation, and other digital capabilities, have allowed manufacturers to reduce sources

60

of error, optimize resources, and reduce patient risk. FDA recognizes the potential for these

61

technologies to provide significant benefits for enhancing the quality, availability, and safety of

62

medical devices, and has undertaken several efforts to help foster the adoption and use of such

63

technologies.

64

65

Specifically, FDA has engaged with stakeholders via the Medical Device Innovation Consortium

66

(MDIC), site visits to medical device manufacturers, and benchmarking efforts with other

67

industries (e.g., automotive, consumer electronics) to keep abreast of the latest technologies and

68

to better understand stakeholders’ challenges and opportunities for further advancement. As part

69

of these ongoing efforts, medical device manufacturers have expressed a desire for greater clarity

70

regarding the Agency’s expectations for software validation for computers and automated data

71

processing systems used as part of production or the quality system. Given the rapidly changing

72

3

Available at https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfStandards/search.cfm.

4

This guidance discusses the “intended use” of computer software used as part of production or the quality system

(see 21 CFR 820.70(i)), which is different from the intended use of the device itself (see 21 CFR 801.4).

Contains Nonbinding Recommendations

Draft – Not for Implementation

6

nature of software, manufacturers have also expressed a desire for a more iterative, agile

73

approach for validation of computer software used as part of production or the quality system.

74

75

Traditionally, software validation has often been accomplished via software testing and other

76

verification activities conducted at each stage of the software development lifecycle. However,

77

as explained in FDA’s Software Validation guidance, software testing alone is often insufficient

78

to establish confidence that the software is fit for its intended use. Instead, the Software

79

Validation guidance recommends that “software quality assurance” focus on preventing the

80

introduction of defects into the software development process, and it encourages use of a risk-

81

based approach for establishing confidence that software is fit for its intended use.

82

83

FDA believes that applying a risk-based approach to computer software used as part of

84

production or the quality system would better focus manufacturers’ assurance activities to help

85

ensure product quality while helping to fulfill the validation requirements of 21 CFR 820.70(i).

86

For these reasons, FDA is now providing recommendations on computer software assurance for

87

computers and automated data processing systems used as part of medical device production or

88

the quality system. FDA believes that these recommendations will help foster the adoption and

89

use of innovative technologies that promote patient access to high-quality medical devices and

90

help manufacturers to keep pace with the dynamic, rapidly changing technology landscape, while

91

promoting compliance with laws and regulations implemented by FDA.

92

93

III. Scope

94

When final, this guidance is intended to provide recommendations regarding computer software

95

assurance for computers or automated data processing systems used as part of production or the

96

quality system.

97

98

This guidance is not intended to provide a complete description of all software validation

99

principles. FDA has previously outlined principles for software validation, including managing

100

changes as part of the software lifecycle, in FDA’s Software Validation guidance.

This guidance

101

applies the risk-based approach to software validation discussed in the Software Validation

102

guidance to production or quality system software. This guidance additionally discusses specific

103

risk considerations, acceptable testing methods, and efficient generation of objective evidence

104

for production or quality system software.

105

106

This guidance does not provide recommendations for the design verification or validation

107

requirements specified in 21 CFR 820.30 when applied to software in a medical device (SiMD)

108

or software as a medical device (SaMD). For more information regarding FDA’s

109

recommendations for design verification or validation of SiMD or SaMD, see the Software

110

Validation guidance.

111

112

IV. ComputerSoftwareAssurance

113

Computer software assurance is a risk-based approach for establishing and maintaining

114

confidence that software is fit for its intended use. This approach considers the risk of

115

Contains Nonbinding Recommendations

Draft – Not for Implementation

7

compromised safety and/or quality of the device (should the software fail to perform as intended)

116

to determine the level of assurance effort and activities appropriate to establish confidence in the

117

software. Because the computer software assurance effort is risk-based, it follows a least-

118

burdensome approach, where the burden of validation is no more than necessary to address the

119

risk. Such an approach supports the efficient use of resources, in turn promoting product quality.

120

121

In addition, computer software assurance establishes and maintains that the software used in

122

production or the quality system is in a state of control throughout its lifecycle (“validated

123

state”). This is important because manufacturers increasingly rely on computers and automated

124

processing systems to monitor and operate production, alert responsible personnel, and transfer

125

and analyze production data, among other uses. By allowing manufacturers to leverage

126

principles such as risk-based testing, unscripted testing, continuous performance monitoring, and

127

data monitoring, as well as validation activities performed by other entities (e.g., developers,

128

suppliers), the computer software assurance approach provides flexibility and agility in helping

129

to assure that the software maintains a validated state consistent with 21 CFR 820.70(i).

130

131

Software that is fit for its intended use and that maintains a validated state should perform as

132

intended, helping to ensure that finished devices will be safe and effective and in compliance

133

with regulatory requirements (see 21 CFR 820.1(a)(1)). Section V below outlines a risk-based

134

framework for computer software assurance.

135

136

V. ComputerSoftwareAssuranceRiskFramework

137

The following approach is intended to help manufacturers establish a risk-based framework for

138

computer software assurance throughout the software’s lifecycle. Examples of applying this risk

139

framework to various computer software assurance situations are provided in Appendix A.

140

IdentifyingtheIntendedUse

141

The regulation requires manufacturers to validate software that is used as part of production or

142

the quality system for its intended use (see 21 CFR 820.70(i)). To determine whether the

143

requirement for validation applies, manufacturers must first determine whether the software is

144

intended for use as part of production or the quality system.

145

146

In general, software used as part of production or the quality system falls into one of two

147

categories: software that is used directly as part of production or the quality system, and software

148

that supports production or the quality system.

149

150

Software with the following intended uses are considered to be used directly as part of

151

production or the quality system:

152

153

· Software intended for automating production processes, inspection, testing, or the

154

collection and processing of production data; and

155

· Software intended for automating quality system processes, collection and processing of

156

quality system data, or maintaining a quality record established under the Quality System

157

regulation.

158

Contains Nonbinding Recommendations

Draft – Not for Implementation

8

159

Software with the following intended uses are considered to be used to support production or

160

the quality system:

161

162

· Software intended for use as development tools that test or monitor software systems or

163

that automate testing activities for the software used as part of production or the quality

164

system, such as those used for developing and running scripts; and

165

· Software intended for automating general record-keeping that is not part of the quality

166

record.

167

168

Both kinds of software are used as “part of” production or the quality system and must be

169

validated under 21 CFR 820.70(i). However, as further discussed below, supporting software

170

often carries lower risk, such that under a risk-based computer software assurance approach, the

171

effort of validation may be reduced accordingly without compromising safety.

172

173

On the other hand, software with the following intended uses generally are not considered to be

174

used as part of production or the quality system, such that the requirement for validation in 21

175

CFR 820.70(i) would not apply:

176

177

· Software intended for management of general business processes or operations, such as

178

email or accounting applications; and

179

· Software intended for establishing or supporting infrastructure not specific to production

180

or the quality system, such as networking or continuity of operations.

181

182

FDA recognizes that software used in production or the quality system is often complex and

183

comprised of several features, functions, and operations;

5

software may have one or more

184

intended uses depending on the individual features, functions, and operations of that software. In

185

cases where the individual features, functions, and operations have different roles within

186

production or the quality system, they may present different risks with different levels of

187

validation effort. FDA recommends that manufacturers examine the intended uses of the

188

individual features, functions, and operations to facilitate development of a risk-based assurance

189

strategy. Manufacturers may decide to conduct different assurance activities for individual

190

features, functions, or operations.

191

192

For example, a commercial off-the-shelf (COTS) spreadsheet software may be comprised of

193

various functions with different intended uses. When utilizing the basic input functions of the

194

COTS spreadsheet software for an intended use of documenting the time and temperature

195

readings for a curing process, a manufacturer may not need to perform additional assurance

196

activities beyond those conducted by the COTS software developer and initial installation and

197

configuration. The intended use of the software, “documenting readings,” only supports

198

maintaining the quality system record and poses a low process risk. As such, initial activities

199

5

That is, software is often an integration of “features,” that are used together to perform a “function” that provides a

desired outcome. Several functions of the software may, in turn, be applied together in an “operation” to perform

practical work in a process. For the purposes of this guidance, a “function” refers to a “software function” and is not

to be confused with a “device function.”

Contains Nonbinding Recommendations

Draft – Not for Implementation

9

such as the vendor assessment and software installation and configuration may be sufficient to

200

establish that the software is fit for its intended use and maintains a validated state. However, if a

201

manufacturer utilizes built-in functions of the COTS spreadsheet to create custom formulas that

202

are directly used in production or the quality system, then additional risks may be present. For

203

example, if a custom formula automatically calculates time and temperature statistics to monitor

204

the performance and suitability of the curing process, then additional validation by the

205

manufacturer might be necessary.

206

207

For the purposes of this guidance, we describe and recommend a computer software assurance

208

framework by examining the intended uses of the individual features, functions, or operations of

209

the software. However, in simple cases where software only has one intended use (e.g., if all of

210

the features, functions, and operations within the software share the same intended use),

211

manufacturers may not find it helpful to examine each feature, function, and operation

212

individually. In such cases, manufacturers may develop a risk-based approach and consider

213

assurance activities based on the intended use of the software overall.

214

215

FDA recommends that manufacturers document their decision-making process for determining

216

whether a software feature, function, or operation is intended for use as part of production or the

217

quality system in their Standard Operating Procedures (SOPs).

218

219

DeterminingtheRiskBasedApproach

220

Once a manufacturer has determined that a software feature, function, or operation is intended

221

for use as part of production or the quality system, FDA recommends using a risk-based analysis

222

to determine appropriate assurance activities. Broadly, this risk-based approach entails

223

systematically identifying reasonably foreseeable software failures, determining whether such a

224

failure poses a high process risk, and systematically selecting and performing assurance activities

225

commensurate with the medical device or process risk, as applicable.

226

227

Note that conducting a risk-based analysis for computer software assurance for production or

228

quality system software is distinct from performing a risk analysis for a medical device as

229

described in ISO 14971:2019 – Medical devices – Application of risk management to medical

230

devices. Unlike the risks contemplated in ISO 14971:2019 for analysis (medical device risks),

231

failures of the production or the quality system software to perform as intended do not occur in a

232

probabilistic manner where an assessment for the likelihood of occurrence for a particular risk

233

could be estimated based on historical data or modeling.

234

235

Instead, the risk-based analysis for production or quality system software considers those factors

236

that may impact or prevent the software from performing as intended, such as proper system

237

configuration and management, security of the system, data storage, data transfer, or operation

238

error. Thus, a risk-based analysis for production or quality system software should consider

239

which failures are reasonably foreseeable (as opposed to likely) and the risks resulting from each

240

such failure. This guidance discusses both process risks and medical device risks. A process risk

241

refers to the potential to compromise production or the quality system. A medical device risk

242

refers to the potential for a device to harm the patient or user. When discussing medical device

243

Contains Nonbinding Recommendations

Draft – Not for Implementation

10

risks, this guidance focuses on the medical device risk resulting from a quality problem that

244

compromises safety.

245

246

Specifically, FDA considers a software feature, function, or operation to pose a high process risk

247

when its failure to perform as intended may result in a quality problem that foreseeably

248

compromises safety, meaning an increased medical device risk. This process risk

249

identification step focuses only on the process, as opposed to the medical device risk posed to the

250

patient or user. Examples of software features, functions, or operations that are generally high

251

process risk are those that:

252

253

· maintain process parameters (e.g., temperature, pressure, or humidity) that affect the

254

physical properties of product or manufacturing processes that are identified as essential

255

to device safety or quality;

256

257

· measure, inspect, analyze and/or determine acceptability of product or process with

258

limited or no additional human awareness or review;

259

260

· perform process corrections or adjustments of process parameters based on data

261

monitoring or automated feedback from other process steps without additional human

262

awareness or review;

263

264

· produce directions for use or other labeling provided to patients and users that are

265

necessary for safe operation of the medical device; and/or

266

267

· automate surveillance, trending, or tracking of data that the manufacturer identifies as

268

essential to device safety and quality.

269

270

In contrast, FDA considers a software feature, function, or operation not to pose a high process

271

risk when its failure to perform as intended would not result in a quality problem that

272

foreseeably compromises safety. This includes situations where failure to perform as

273

intended would not result in a quality problem, as well as situations where failure to

274

perform as intended may result in a quality problem that does not foreseeably lead to

275

compromised safety. Examples of software features, functions, or operations that generally are

276

not high process risk include those that:

277

278

· collect and record data from the process for monitoring and review purposes that do not

279

have a direct impact on production or process performance;

280

281

· are used as part the quality system for Corrective and Preventive Actions (CAPA)

282

routing, automated logging/tracking of complaints, automated change control

283

management, or automated procedure management;

284

285

· are intended to manage data (process, store, and/or organize data), automate an existing

286

calculation, increase process monitoring, or provide alerts when an exception occurs in an

287

established process; and/or

288

Contains Nonbinding Recommendations

Draft – Not for Implementation

11

289

· are used to support production or the quality system, as explained in Section V.A. above.

290

291

FDA acknowledges that process risks associated with software used as part of production or the

292

quality system are on a spectrum, ranging from high risk to low risk. Manufacturers should

293

determine the risk of each software feature, function, or operation as the risk falls on that

294

spectrum, depending on the intended use of the software. However, FDA is primarily concerned

295

with the review and assurance for those software features, functions, and operations that are high

296

process risk because a failure also poses a medical device risk. Therefore, for the purposes of this

297

guidance, FDA is presenting the process risks in a binary manner, “high process risk” and “not

298

high process risk.” A manufacturer may still determine that a process risk is, for example,

299

“moderate,” “intermediate,” or even “low” for purposes of determining assurance activities; in

300

such a case, the portions of this guidance concerning “not high process risk” would apply. As

301

discussed in Section V.C. below, assurance activities should be conducted for software that is

302

“high process risk” and “not high process risk” commensurate with the risk.

303

304

Example 1: An Enterprise Resource Planning (ERP) Management system contains a feature that

305

automates manufacturing material restocking. This feature ensures that the right materials are

306

ordered and delivered to appropriate production operations. However, a qualified person checks

307

the materials before their use in production. The failure of this feature to perform as intended

308

may result in a mix-up in restocking and delivery, which would be a quality problem because the

309

wrong materials would be restocked and delivered. However, the delivery of the wrong materials

310

to the qualified person should result in the rejection of those materials before use in production;

311

as such, the quality problem should not foreseeably lead to compromised safety. The

312

manufacturer identifies this as an intermediate (not high) process risk and determines assurance

313

activities commensurate with the process risk. The manufacturer already undertakes some of

314

those identified assurance activities so implements only the remaining identified assurance

315

activities.

316

317

Example 2: A similar feature in another ERP management system performs the same tasks as in

318

the previous example except that it also automates checking the materials before their use in

319

production. A qualified person does not check the material first. The manufacturer identifies this

320

as a high process risk because the failure of the feature to perform as intended may result in a

321

quality problem that foreseeably compromises safety. As such, the manufacturer will determine

322

assurance activities that are commensurate with the related medical device risk. The

323

manufacturer already undertakes some of those identified assurance activities so implements

324

only the remaining identified assurance activities.

325

326

Example 3: An ERP management system contains a feature to automate product delivery. The

327

medical device risk depends upon, among other factors, the correct product being delivered to

328

the device user. A failure of this feature to perform as intended may result in a delivery mix-up,

329

which would be a quality problem that foreseeably compromises safety; as such, the

330

manufacturer identifies this as a high process risk. Since the failure would compromise safety,

331

the manufacturer will next determine the related increase in device risk and identify the

332

assurance activities that are commensurate with the device risk. In this case, the manufacturer

333

Contains Nonbinding Recommendations

Draft – Not for Implementation

12

has not already implemented any of the identified assurance activities so implements all of the

334

assurance activities identified in the analysis.

335

336

Example 4: An automated graphical user interface (GUI) function in the production software is

337

used for developing test scripts based on user interactions and to automate future testing of

338

modifications to the user interface of a system used in production. A failure of this GUI function

339

to perform as intended may result in implementation disruptions and delay updates to the

340

production system, but in this case, these errors should not foreseeably lead to compromised

341

safety because the GUI function operates in a separate test environment. The manufacturer

342

identifies this as a low (not high) process risk and determines assurance activities that are

343

commensurate with the process risk. The manufacturer already undertakes some of those

344

identified assurance activities so implements only the remaining identified assurance activities.

345

346

As noted in FDA’s guidance, “30-Day Notices, 135 Day Premarket Approval (PMA)

347

Supplements and 75-Day Humanitarian Device Exemption (HDE) Supplements for

348

Manufacturing Method or Process Changes,”

6

for devices subject to a PMA or HDE, changes to

349

the manufacturing procedure or method of manufacturing that do not affect the safety or

350

effectiveness of the device must be submitted in a periodic report (usually referred to as an

351

annual report).

7

In contrast, modifications to manufacturing procedures or methods of

352

manufacture that affect the safety and effectiveness of the device must be submitted in a 30-day

353

notice.

8

Changes to the manufacturing procedure or method of manufacturing may include

354

changes to software used in production or the quality system. For an addition or change to

355

software used in production or the quality system of devices subject to a PMA or HDE, FDA

356

recommends that manufacturers apply the principles outlined above in determining whether the

357

change may affect the safety or effectiveness of the device. In general, if a change may result in a

358

quality problem that foreseeably compromises safety, then it should be submitted in a 30-day

359

notice. If a change would not result in a quality problem that foreseeably compromises safety, an

360

annual report may be appropriate.

361

362

For example, a Manufacturing Execution System (MES) may be used to manage workflow, track

363

progress, record data, and establish alerts or thresholds based on validated parameters, which are

364

part of maintaining the quality system. Failure of such an MES to perform as intended may

365

disrupt operations but not affect the process parameters established to produce a safe and

366

effective device. Changes affecting these MES operations are generally considered annually

367

reportable. In contrast, an MES used to automatically control and adjust established critical

368

production parameters (e.g., temperature, pressure, process time) may be a change to a

369

manufacturing procedure that affects the safety or effectiveness of the device. If so, changes

370

affecting this specific operation would require a 30-day notice.

371

372

6

Available at https://www.fda.gov/regulatory-information/search-fda-guidance-documents/30-day-notices-135-day-

premarket-approval-pma-supplements-and-75-day-humanitarian-device-exemption.

7

21 CFR 814.39(b), 814.126(b)(1), and https://www.fda.gov/regulatory-information/search-fda-guidance-

documents/annual-reports-approved-premarket-approval-applications-pma.

8

21 CFR 814.39(b), 814.126(b)(1). Changes in manufacturing/sterilization site or to design or performance

specifications do not qualify for a 30-day notice.

Contains Nonbinding Recommendations

Draft – Not for Implementation

13

DeterminingtheAppropriateAssuranceActivities

373

Once the manufacturer has determined whether a software feature, function, or operation poses a

374

high process risk (a quality problem that may foreseeably compromise safety), the manufacturer

375

should identify the assurance activities commensurate with the medical device risk or the process

376

risk. In cases where the quality problem may foreseeably compromise safety (high process risk),

377

the level of assurance should be commensurate with the medical device risk. In cases where the

378

quality problem may not foreseeably compromise safety (not high process risk), the level of

379

assurance rigor should be commensurate with the process risk. In either case, heightened risks of

380

software features, functions, or operations generally entail greater rigor, i.e., a greater amount of

381

objective evidence. Conversely, relatively less risk (i.e., not high process risk) of compromised

382

safety and/or quality generally entails less collection of objective evidence for the computer

383

software assurance effort.

384

385

A feature, function, or operation that could lead to severe harm to a patient or user would

386

generally be high device risk. In contrast, a feature, function, or operation that would not

387

foreseeably lead to severe harm would likely not be high device risk. In either case, the risk of

388

the software’s failure to perform as intended is commensurate with the resulting medical device

389

risk.

390

391

If the manufacturer instead determined that the software feature, function, or operation does not

392

pose a high process risk (i.e., it would not lead to a quality problem that foreseeably

393

compromises safety), the manufacturer should consider the risk relative to the process, i.e.,

394

production or the quality system. This is because the failure would not compromise safety, so the

395

failure would not introduce additional medical device risk. For example, a function that collects

396

and records process data for review would pose a lower process risk than a function that

397

determines acceptability of product prior to human review.

398

399

Types of assurance activities commonly performed by manufacturers include, but are not limited

400

to, the following:

401

402

· Unscripted testing – Dynamic testing in which the tester’s actions are not prescribed by

403

written instructions in a test case.

9

It includes:

404

405

· Ad-hoc testing – A concept derived from unscripted practice that focuses primarily

406

on performing testing that does not rely on large amounts of documentation (e.g., test

407

procedures) to execute.

10

408

409

· Error-guessing – A test design technique in which test cases are derived on the basis

410

of the tester’s knowledge of past failures or general knowledge of failure modes.

11

411

412

9

IEC/IEEE/ISO 29119-1 First edition 2013-09-01: Software and systems engineering – Software testing - Part 1:

Concepts and definitions, Section 4.94.

10

Ibid., Section 5.6.5.

11

Ibid., Section 4.14.

Contains Nonbinding Recommendations

Draft – Not for Implementation

14

· Exploratory testing – Experience-based testing in which the tester spontaneously

413

designs and executes tests based on the tester’s existing relevant knowledge, prior

414

exploration of the test item (including results from previous tests), and heuristic

415

“rules of thumb” regarding common software behaviors and types of failure.

416

Exploratory testing looks for hidden properties, including hidden, unanticipated user

417

behaviors, or accidental use situations that could interfere with other software

418

properties being tested and could pose a risk of software failure.

12

419

420

· Scripted testing – Dynamic testing in which the tester’s actions are prescribed by written

421

instructions in a test case. Scripted testing includes both robust and limited scripted

422

testing.

13

423

424

· Robust scripted testing – Scripted testing efforts in which the risk of the computer

425

system or automation includes evidence of repeatability, traceability to requirements,

426

and auditability.

427

428

· Limited scripted testing – A hybrid approach of scripted and unscripted testing that

429

is appropriately scaled according to the risk of the computer system or automation.

430

This approach may apply scripted testing for high-risk features or operations and

431

unscripted testing for low- to medium-risk items as part of the same assurance effort.

432

433

In general, FDA recommends that manufacturers apply principles of risk-based testing in which

434

the management, selection, prioritization, and use of testing activities and resources are

435

consciously based on corresponding types and levels of analyzed risk to determine the

436

appropriate activities.

14

For high-risk software features, functions, and operations, manufacturers

437

may choose to consider more rigor such as the use of scripted testing or limited scripted testing,

438

as appropriate, when determining their assurance activities. In contrast, for software features,

439

functions, and operations that are not high-risk, manufacturers may consider using unscripted

440

testing methods such as ad-hoc testing, error-guessing, exploratory testing, or a combination of

441

methods that is suitable for the risk of the intended use.

442

443

When deciding on the appropriate assurance activities, manufacturers should consider whether

444

there are any additional controls or mechanisms in place throughout the quality system that may

445

decrease the impact of compromised safety and/or quality if failure of the software feature,

446

function or operation were to occur. For example, as part of a comprehensive assurance

447

approach, manufacturers can leverage the following to reduce the effort of additional assurance

448

activities:

449

450

· Activities, people, and established processes that provide control in production. Such

451

activities may include procedures to ensure integrity in the data supporting production or

452

software quality assurance processes performed by other organizational units.

453

454

12

Ibid., Section 4.16.

13

Ibid., Section 4.37.

14

Ibid., Section 4.35.

Contains Nonbinding Recommendations

Draft – Not for Implementation

15

· Established purchasing control processes for selecting and monitoring software

455

developers. For example, the manufacturer could incorporate the practices, validation

456

work, and electronic information already performed by developers of the software as the

457

starting point and determine what additional activities may be needed. For some lower-

458

risk software features, functions, and operations, this may be all the assurance that is

459

needed by the manufacturer.

460

461

· Additional process controls that have been incorporated throughout production. For

462

example, if a process is fully understood, all critical process parameters are monitored,

463

and/or all outputs of a process undergo verification testing, these controls can serve as

464

additional mechanisms to detect and correct the occurrence of quality problems that may

465

occur if a software feature, function, or operation were to fail to perform as intended. In

466

this example, the presence of these controls can be leveraged to reduce the effort of

467

assurance activities appropriate for the software.

468

469

· The data and information periodically or continuously collected by the software for the

470

purposes of monitoring or detecting issues and anomalies in the software after

471

implementation of the software. The capability to monitor and detect performance issues

472

or deviations and system errors may reduce the risk associated with a failure of the

473

software to perform as intended and may be considered when deciding on assurance

474

activities.

475

476

· The use of Computer System Validation tools (e.g., bug tracker, automated testing) for

477

the assurance of software used in production or as part of the quality system whenever

478

possible.

479

480

· The use of testing done in iterative cycles and continuously throughout the lifecycle of

481

the software used in production or as part of the quality system.

482

483

For example, supporting software, as referenced in Section V.A., often carries lower risk, such

484

that the assurance effort may generally be reduced accordingly. Because assurance activities

485

used “directly” in production or the quality system often inherently cover the performance of

486

supporting software, assurance that this supporting software performs as intended may be

487

sufficiently established by leveraging vendor validation records, software installation, or

488

software configuration, such that additional assurance activities (e.g., scripted or unscripted

489

testing) may be unnecessary.

490

491

Manufacturers are responsible for determining the appropriate assurance activities for ensuring

492

the software features, functions, or operations maintain a validated state. The assurance activities

493

and considerations noted above are some possible ways of providing assurance and are not

494

intended to be prescriptive or exhaustive. Manufacturers may leverage any of the activities or a

495

combination of activities that are most appropriate for risk associated with the intended use.

496

497

Contains Nonbinding Recommendations

Draft – Not for Implementation

16

EstablishingtheAppropriateRecord

498

When establishing the record, the manufacturer should capture sufficient objective evidence to

499

demonstrate that the software feature, function, or operation was assessed and performs as

500

intended. In general, the record should include the following:

501

502

· the intended use of the software feature, function, or operation;

503

· the determination of risk of the software feature, function, or operation;

504

· documentation of the assurance activities conducted, including:

505

· description of the testing conducted based on the assurance activity;

506

· issues found (e.g., deviations, failures) and the disposition;

507

· conclusion statement declaring acceptability of the results;

508

· the date of testing/assessment and the name of the person who conducted the

509

testing/assessment;

510

· established review and approval when appropriate (e.g., when necessary, a

511

signature and date of an individual with signatory authority)

512

513

Documentation of assurance activities need not include more evidence than necessary to show

514

that the software feature, function, or operation performs as intended for the risk identified. FDA

515

recommends the record retain sufficient details of the assurance activity to serve as a baseline for

516

improvements or as a reference point if issues occur.

15

517

518

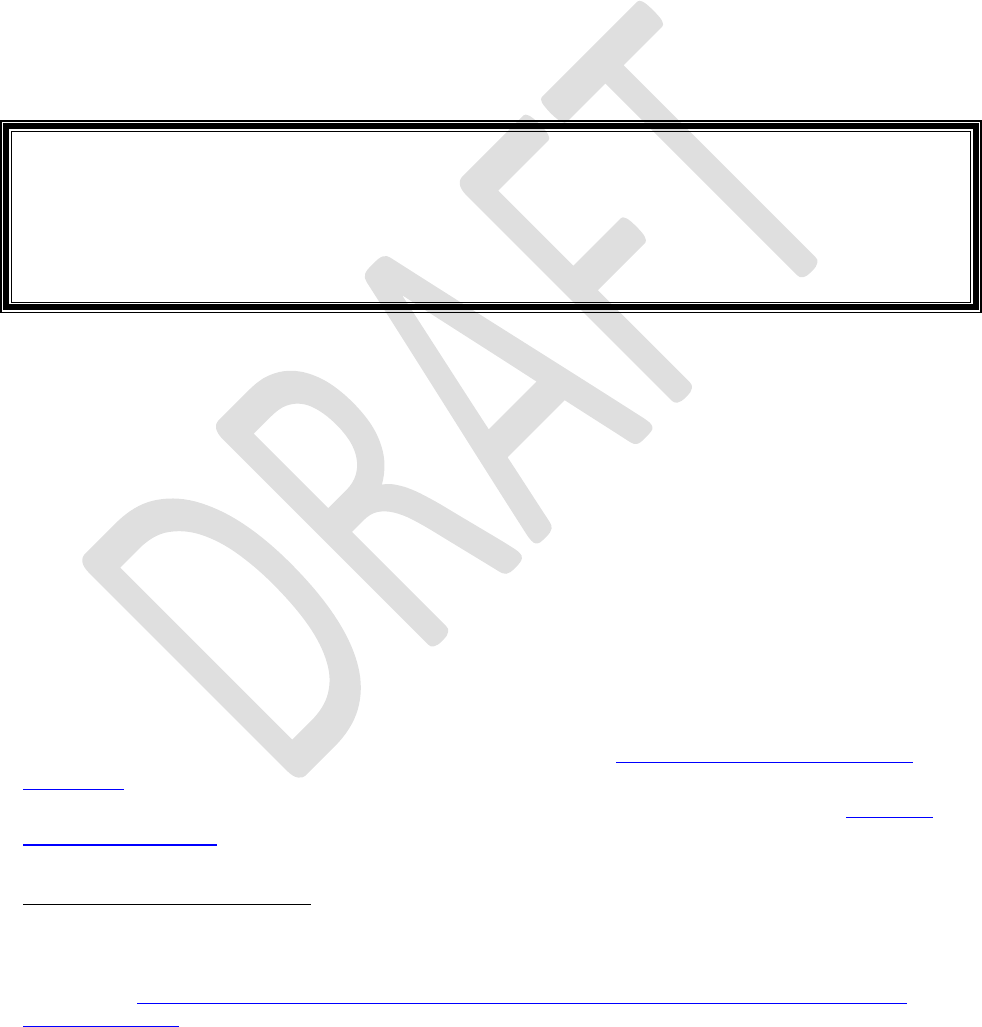

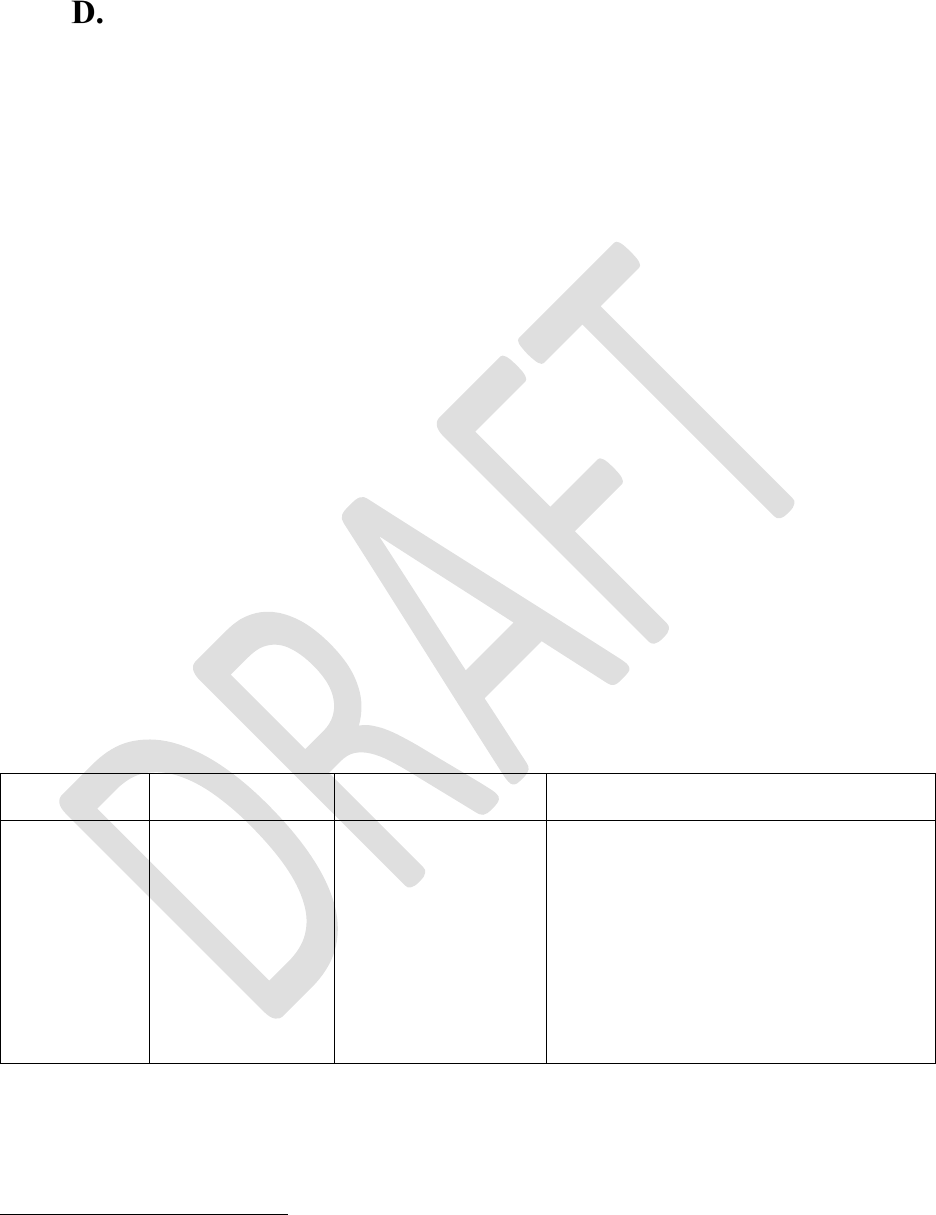

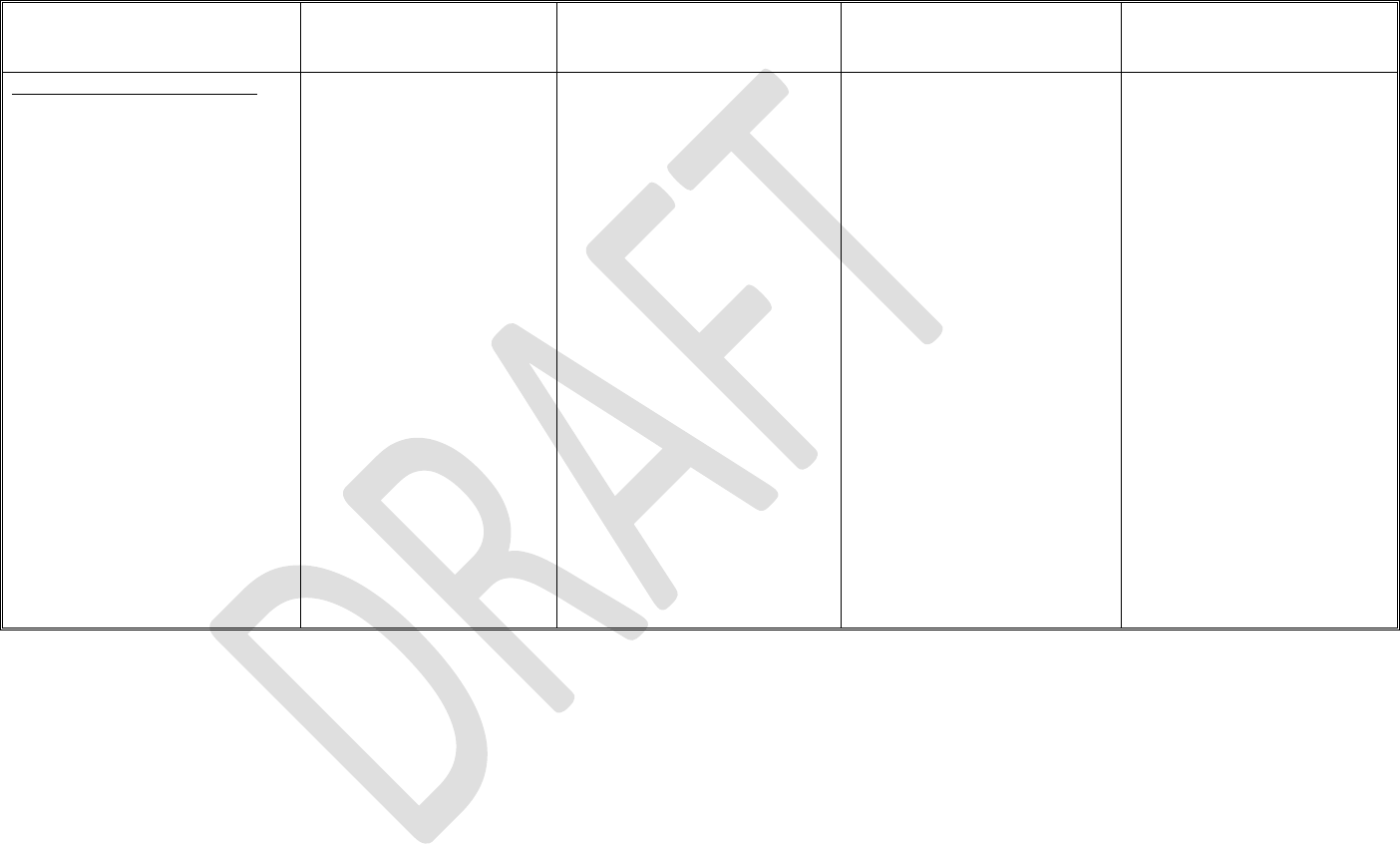

Table 1 provides some examples of ways to implement and develop the record when using the

519

risk-based testing approaches identified in Section V.C. above. Manufacturers may use

520

alternative approaches and provide different documentation so long as their approach satisfies

521

applicable legal documentation requirements.

522

523

Table 1 – Examples of Assurance Activities and Records

524

Assurance

Activity

Test Plan

Test Results

Record

(Including Digital)

Scripted

Testing:

Robust

· Test objectives

· Test cases

(step-by-step

procedure)

· Expected

results

· Independent

review and

approval of test

cases

· Pass/fail for test

case

· Details regarding

any

failures/deviations

found

· Intended use

· Risk determination

· Detailed report of testing performed

· Pass/fail result for each test case

· Issues found and disposition

· Conclusion statement

· Record of who performed testing and

date

· Established review and approval when

appropriate

15

For the Quality System regulation’s general requirements for records, including record retention period, see 21

CFR 820.180.

Contains Nonbinding Recommendations

Draft – Not for Implementation

17

Assurance

Activity

Test Plan

Test Results

Record

(Including Digital)

Scripted

Testing:

Limited

· Limited test

cases (step-by-

step procedure)

identified

· Expected

results for the

test cases

· Identify

unscripted

testing applied

· Independent

review and

approval of test

plan

· Pass/fail for test

case identified

· Details regarding

any

failures/deviations

found

· Intended use

· Risk determination

· Summary description of testing

performed

· Pass/fail test result for each test case

· Issues found and disposition

· Conclusion statement

· Record of who performed testing and

date

· Established review and approval when

appropriate

Unscripted

Testing:

Ad-hoc

· Testing of

features and

functions with

no test plan

· Details regarding

any

failures/deviations

found

· Intended use

· Risk determination

· Summary description of features and

functions tested and testing performed

· Issues found and disposition

· Conclusion statement

· Record of who performed testing and

date of testing

· Established review and approval when

appropriate

Unscripted

Testing:

Error guessing

· Testing of

failure-modes

with no test

plan

· Details regarding

any failures/

deviations found

· Intended use

· Risk determination

· Summary description of failure-modes

tested and testing performed

· Issues found and disposition

· Conclusion statement

· Record of who performed testing and

date of testing

· Established review and approval when

appropriate

Unscripted

Testing:

Exploratory

Testing

· Establish high

level test plan

objectives (no

step-by-step

procedure is

necessary)

· Pass/fail for each

test plan objective

· Details regarding

any

failures/deviations

found

· Intended use

· Risk determination

· Summary description of the objectives

tested and testing performed

· Pass/fail test result for each objective

· Issues found and disposition

· Conclusion statement

· Record of who performed testing and

date of testing

· Established review and approval when

appropriate

525

526

527

528

Contains Nonbinding Recommendations

Draft – Not for Implementation

18

The following is an example of a record of assurance in a scenario where a manufacturer has

529

developed a spreadsheet with the intended use of collecting and graphing nonconformance data

530

stored in a controlled system for monitoring purposes. In this example, the manufacturer has

531

established additional process controls and inspections that ensure non-conforming product is not

532

released. In this case, failure of the spreadsheet to perform as intended would not result in a

533

quality problem that foreseeably leads to compromised safety, so the spreadsheet would not pose

534

a high process risk. The manufacturer conducted rapid exploratory testing of specific functions

535

used in the spreadsheet to ensure that analyses can be created, read, updated, and/or deleted.

536

During exploratory testing, all calculated fields updated correctly except for one deviation that

537

occurred during update testing. In this scenario, the record would be documented as follows:

538

539

· Intended Use: The spreadsheet is intended for use in collecting and graphing

540

nonconformance data stored in a controlled system for monitoring purposes; as such, it is

541

used as part of production or the quality system. Because of this use, the spreadsheet is

542

different from similar software used for business operations such as for accounting.

543

544

· Risk-Based Analysis: In this case, the software is only used to collect and display data

545

for monitoring nonconformances, and the manufacturer has established additional process

546

controls and inspections to ensure that nonconforming product is not released. Therefore,

547

failure of the spreadsheet to perform as intended should not result in a quality problem

548

that foreseeably leads to compromised safety. As such, the software does not pose a high

549

process risk, and the assurance activities should be commensurate with the process risk.

550

551

· Tested: Spreadsheet X, Version 1.2

552

553

· Test type: Unscripted testing – exploratory testing

554

555

· Goal: Ensure that analyses can be correctly created, read, updated, and deleted

556

557

· Testing objectives and activities:

558

559

o Create new analysis – Passed

560

o Read data from the required source – Passed

561

o Update data in the analysis – Failed due to input error, then passed

562

o Delete data – Passed

563

o Verify through observation that all calculated fields correctly update with changes

564

– Passed with noted deviation

565

566

· Deviation: During update testing, when the user inadvertently input text into an

567

updatable field requiring numeric data, the associated row showed an immediate error.

568

569

· Conclusion: No errors were observed in the spreadsheet functions beyond the deviation.

570

Incorrectly inputting text into the field is immediately visible and does not impact the risk

571

of the intended use. In addition, a validation rule was placed on the field to permit only

572

numeric data inputs.

573

Contains Nonbinding Recommendations

Draft – Not for Implementation

19

574

· When/Who: July 9, 2019, by Jane Smith

575

576

Advances in digital technology may allow for manufacturers to leverage automated traceability,

577

testing, and the electronic capture of work performed to document the results, reducing the need

578

for manual or paper-based documentation. As a least burdensome method, FDA recommends the

579

use of electronic records, such as system logs, audit trails, and other data generated by the

580

software, as opposed to paper documentation and screenshots, in establishing the record

581

associated with the assurance activities.

582

583

Manufacturers have expressed confusion and concern regarding the application of Part 11,

584

Electronic Records; Electronic Signatures, to computers or automated data processing systems

585

used as part of production or the quality system. As described in the “Part 11, Electronic

586

Records; Electronic Signatures – Scope and Application” guidance,

16

the Agency intends to

587

exercise enforcement discretion regarding Part 11 requirements for validation of computerized

588

systems used to create, modify, maintain, or transmit electronic records (see 21 CFR 11.10(a)

589

and 11.30). In general, Part 11 applies to records in electronic form that are created, modified,

590

maintained, archived, retrieved, or transmitted under any records requirements set forth in

591

Agency regulations (see 21 CFR 11.1(b)). Part 11 also applies to electronic records submitted to

592

the Agency under requirements of the Federal Food, Drug, and Cosmetic Act (FD&C Act) and

593

the Public Health Service Act (PHS Act), even if such records are not specifically identified in

594

Agency regulations (see 21 CFR 11.1(b)).

595

596

In the context of computer or automated data processing systems, for computer software used as

597

part of production or the quality system, a document required under Part 820 and maintained in

598

electronic form would generally be an “electronic record” within the meaning of Part 11 (see 21

599

CFR 11.3(b)(6)). For example, if a document requires a signature under Part 820 and is

600

maintained in electronic form, then Part 11 applies (see, e.g., 21 CFR 820.40 (requiring

601

signatures for control of required documents)).

602

16

https://www.fda.gov/regulatory-information/search-fda-guidance-documents/part-11-electronic-records-

electronic-signatures-scope-and-application.

Contains Nonbinding Recommendations

Draft – Not for Implementation

20

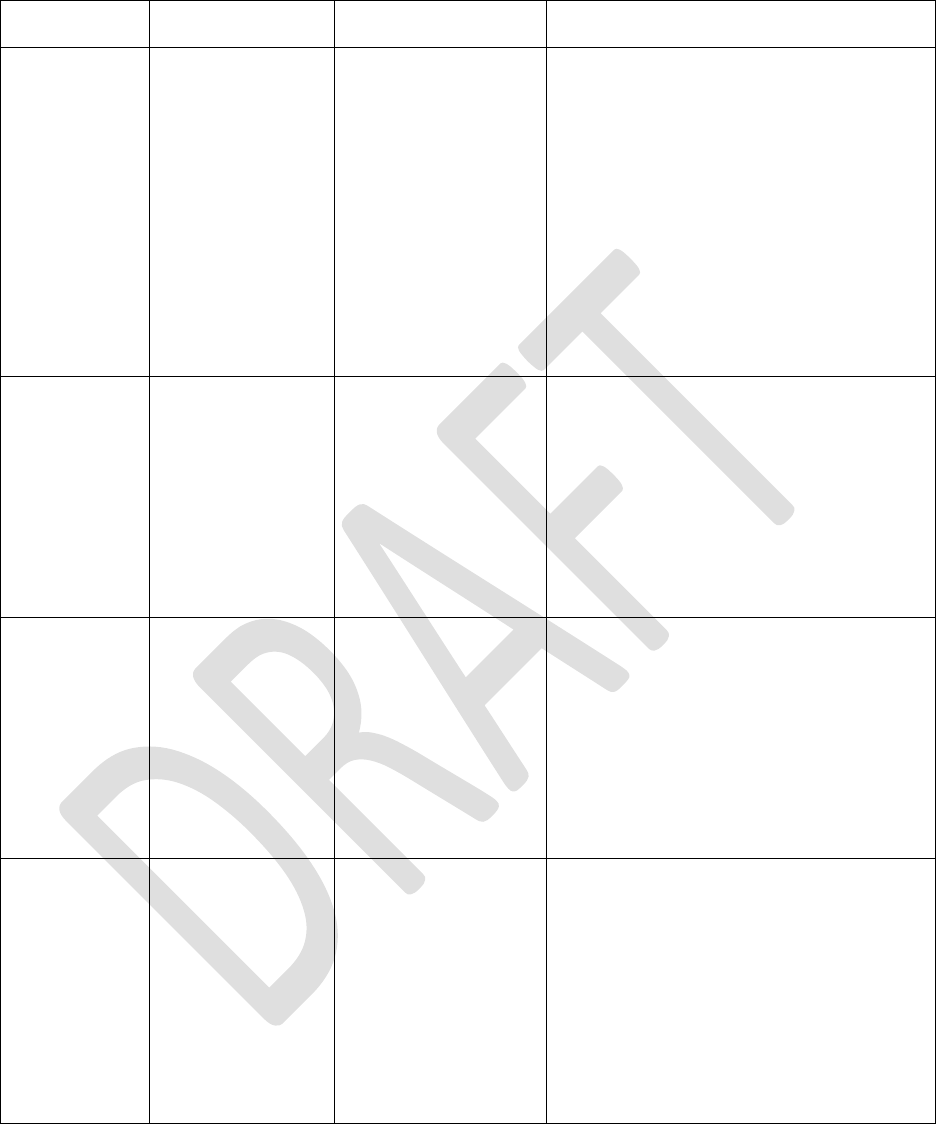

AppendixA.Examples603

The examples in this section outline possible application of the principles in this draft guidance to various software assurance 604

situations cases.605

Example1:NonconformanceManagementSystem606

A manufacturer has purchased COTS software for automating their nonconformance process and is applying a risk-based approach for 607

computer software assurance in its implementation. The software is intended to manage the nonconformance process electronically. 608

The following features, functions, or operations were considered by the manufacturer in developing a risk-based assurance strategy:609

610

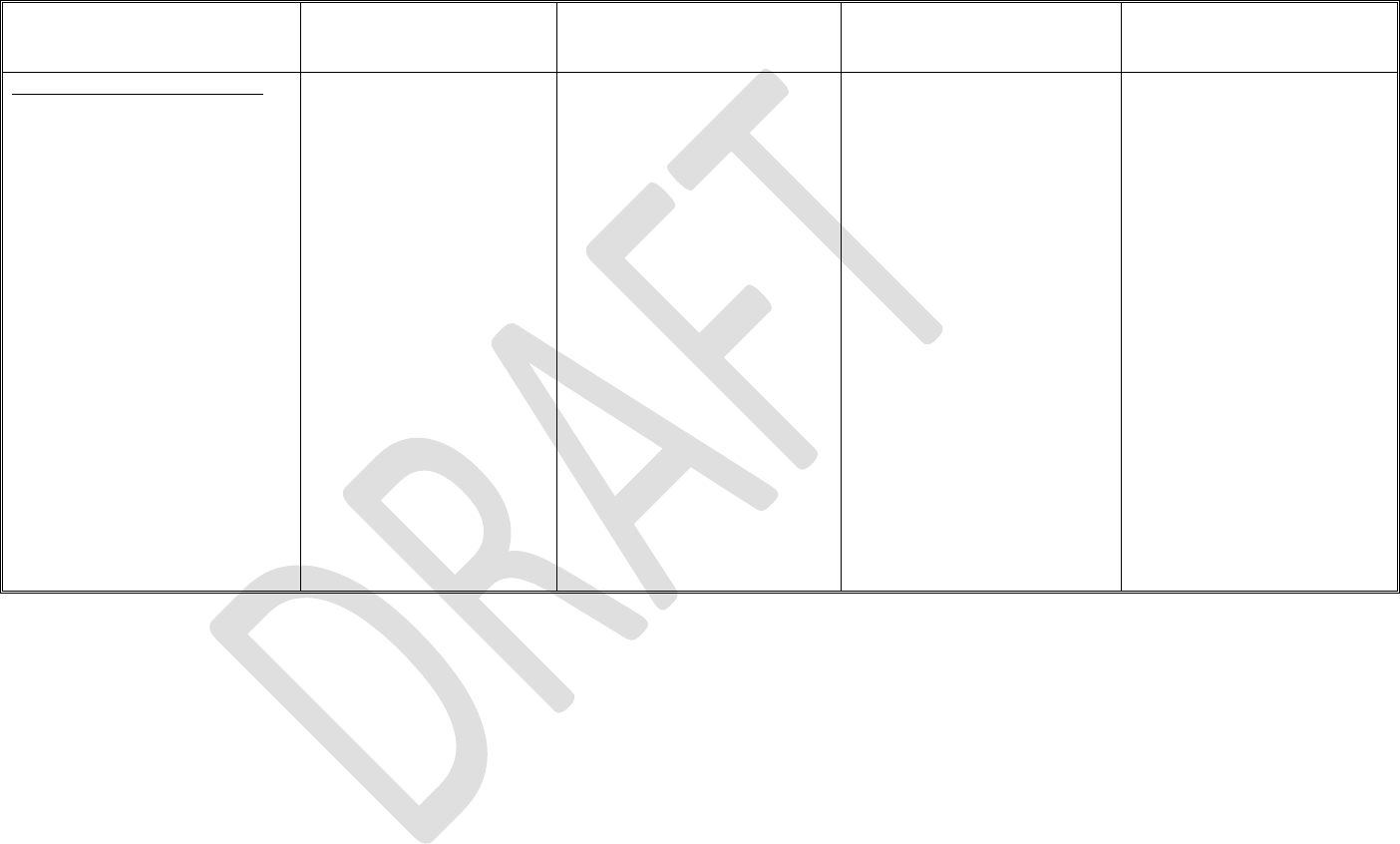

Table 2. Computer Software Assurance Example for a Nonconformance Management System611

Features, Functions, or

Operations

Intended Use of the

Features, Functions or

Operations

Risk-Based Analysis

Assurance Activities

Establishing the appropriate

record

Nonconformance (NC) Initiation

Operations:

· A nonconforming event

results in the creation of an

NC record.

· The necessary data for

initiation are recorded prior to

completion of an NC

initiation task.

· An NC Owner is assigned

prior to completion of the NC

initiation task.

The intended uses of the

operations are to manage the

workflow of the

nonconformance and to

error-proof the workflow to

facilitate the work and a

complete quality record.

These operations are

intended to supplement

processes established by the

manufacturer for

containment of non-

conforming product.

Failure of the NC initiation

operation to perform as intended

may delay the initiation

workflow, but would not result

in a quality problem that

foreseeably compromises safety,

as the manufacturer has

additional processes in place for

containment of non-conforming

product. As such, the

manufacturer determined the NC

initiation operations did not pose

a high process risk.

The manufacturer has

performed an assessment of the

system capability, supplier

evaluation, and installation

activities. In addition, the

manufacturer supplements these

activities with exploratory

testing of the operations. High

level objectives for testing are

established to meet the intended

use and no unanticipated

failures occur.

The manufacturer documents:

· the intended use

· risk determination,

· summary description of the

features, functions,

operations tested

· the testing objectives and

if they passed or failed

· any issues found and their

disposition

· a concluding statement

noting that the

performance of the

operation is acceptable

· the date testing was

performed, and who

performed the testing.

Contains Nonbinding Recommendations

Draft – Not for Implementation

21

Features, Functions, or

Operations

Intended Use of the

Features, Functions or

Operations

Risk-Based Analysis

Assurance Activities

Establishing the appropriate

record

Electronic Signature Function:

· The electronic signature

execution record is stored as

part of the audit trail.

· The electronic signature

employs two distinct

identification components of

a login and password.

· When an electronic signature

is executed, the following

information is part of the

execution record:

o The name of the person

who signs the record

o The date (DD-MM-

YYYY) and time

(hh:mm) the signature

was executed.

o The meaning associated

with the signature (such

as review, approval,

responsibility, or

authorship).

The intended use of the

electronic signature function

is to capture and store an

electronic signature where a

signature is required and

such that it meets

requirements for electronic

signatures.

If the electronic signature

function were to fail to perform

as intended, then production or

quality system records may not

reflect appropriate approval or

be sufficiently auditable, or may

fail to meet other regulatory

requirements. However, such a

failure would not foreseeably

lead to compromised safety. As

such, the manufacturer

determined that this function

does not pose high process risk.

The manufacturer has

performed an assessment of the

system capability, supplier

evaluation, and installation

activities. To provide assurance

that the function complies with

applicable requirements, the

manufacturer performs ad-hoc

testing of this function with

users to demonstrate the

function meets the intended use.

The manufacturer documents:

· the intended use

· risk determination

· testing performed

· any issues found and their

disposition

· a concluding statement

noting that the

performance of the

function is acceptable

· the date testing was

performed and who

performed the testing.

Contains Nonbinding Recommendations

Draft – Not for Implementation

22

Features, Functions, or

Operations

Intended Use of the

Features, Functions or

Operations

Risk-Based Analysis

Assurance Activities

Establishing the appropriate

record

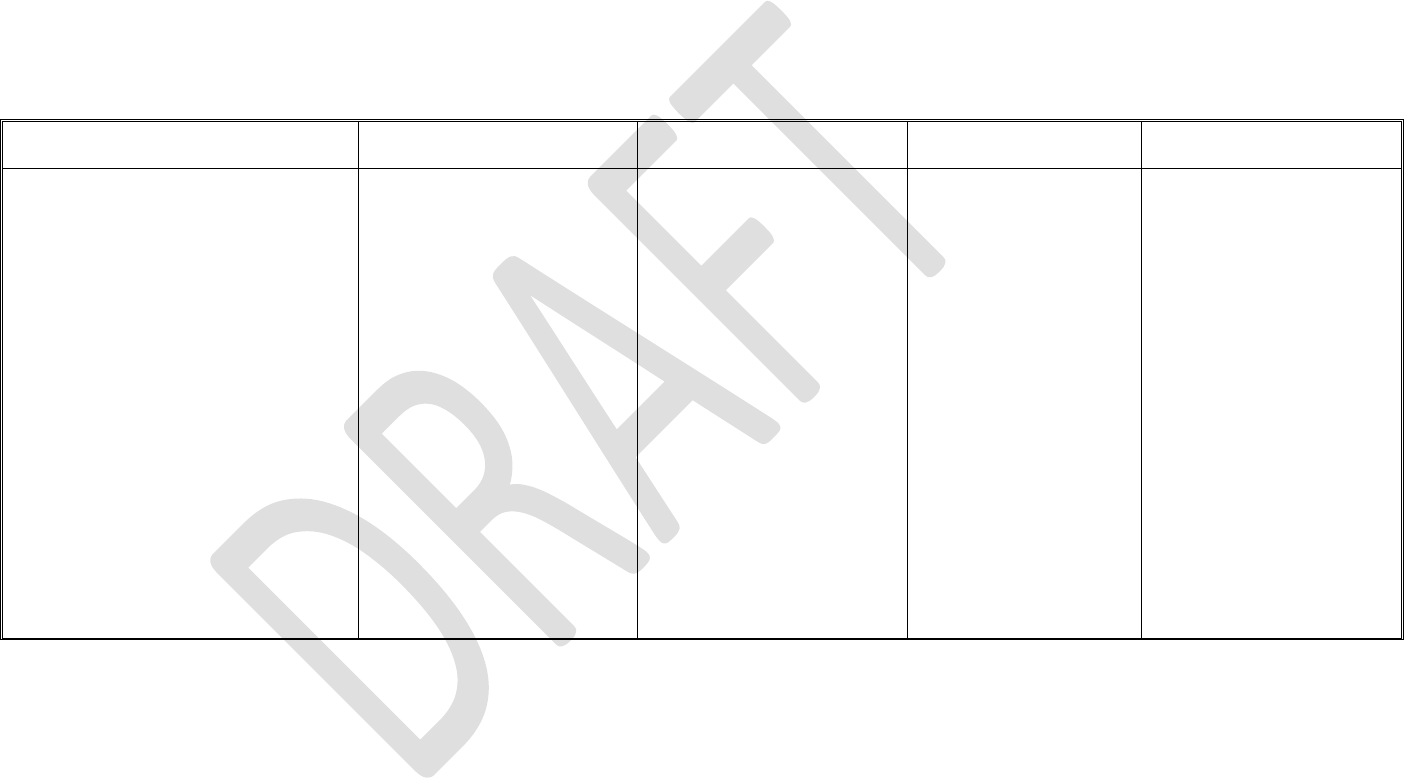

Product Containment Function:

· When a nonconformance is

initiated for product outside

of the manufacturer’s control,

then the system prompts the

user to identify if a product

correction or removal is

needed.

This function is intended to

trigger the necessary

evaluation and decision-

making on whether a product

correction or removal is

needed when the

nonconformance occurred in

product that has been

distributed.

Failure of the function to

perform as intended would

result in a necessary correction

or removal not being initiated,

resulting in a quality problem

that foreseeably compromises

safety. The manufacturer

therefore determined that this

function poses high process risk.

The manufacturer has

performed an assessment of the

system capability, supplier

evaluation, and installation

activities. Since the

manufacturer determined the

function to pose high process

risk, the manufacturer

determined assurance activities

commensurate with the medical

device risk: established a

detailed scripted test protocol

that exercises the possible

interactions and potential ways

the function could fail. The

testing also included

appropriate repeatability testing

in various scenarios to provide

assurance that the function

works reliably.

The manufacturer documents:

· the intended use

· risk determination

· detailed test protocol

developed

· detailed report of the

testing performed

· pass/fail results for each

test case

· any issues found and their

disposition

· a concluding statement

noting that the

performance of the

operation is acceptable

· the date testing was

performed and who

performed the testing

· the signature and date of

the appropriate signatory

authority.

612

613

614

615

616

Contains Nonbinding Recommendations

Draft – Not for Implementation

23

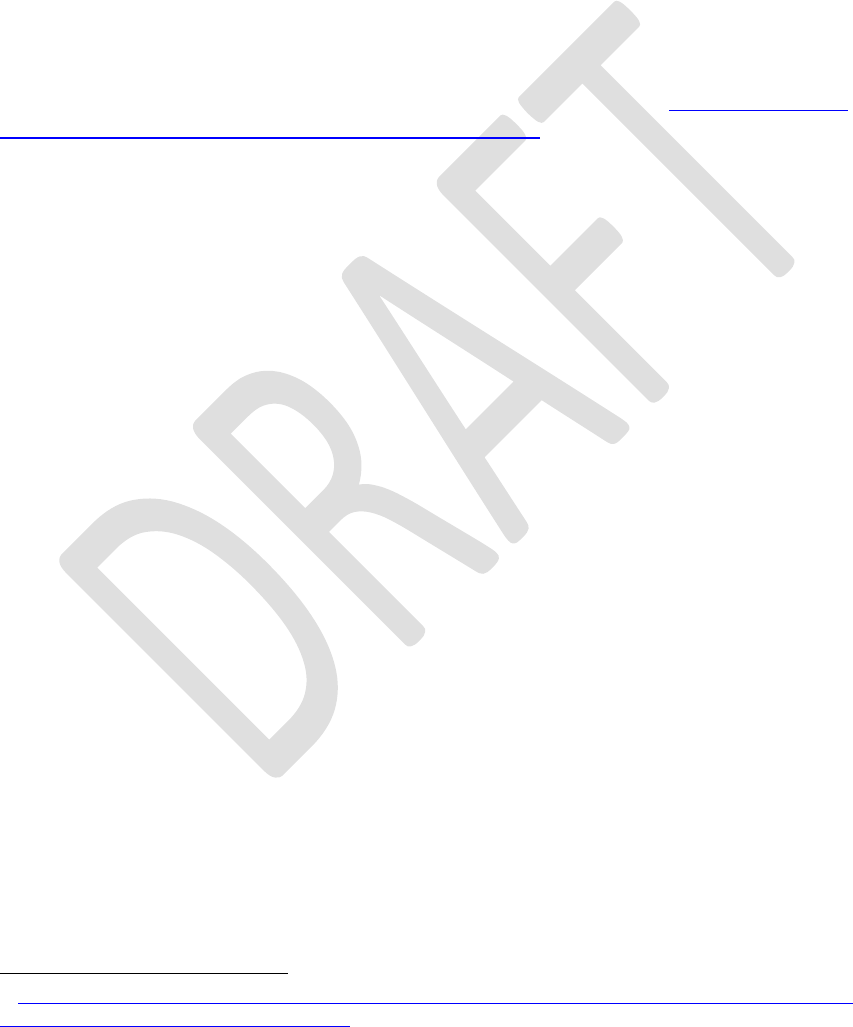

Example2:LearningManagementSystem(LMS)617

A manufacturer is implementing a COTS LMS and is applying a risk-based approach for computer software assurance in its 618

implementation. The software is intended to manage, record, track, and report on training. The following features, functions, or 619

operations were considered by the manufacturer in developing a risk-based assurance strategy: 620

621

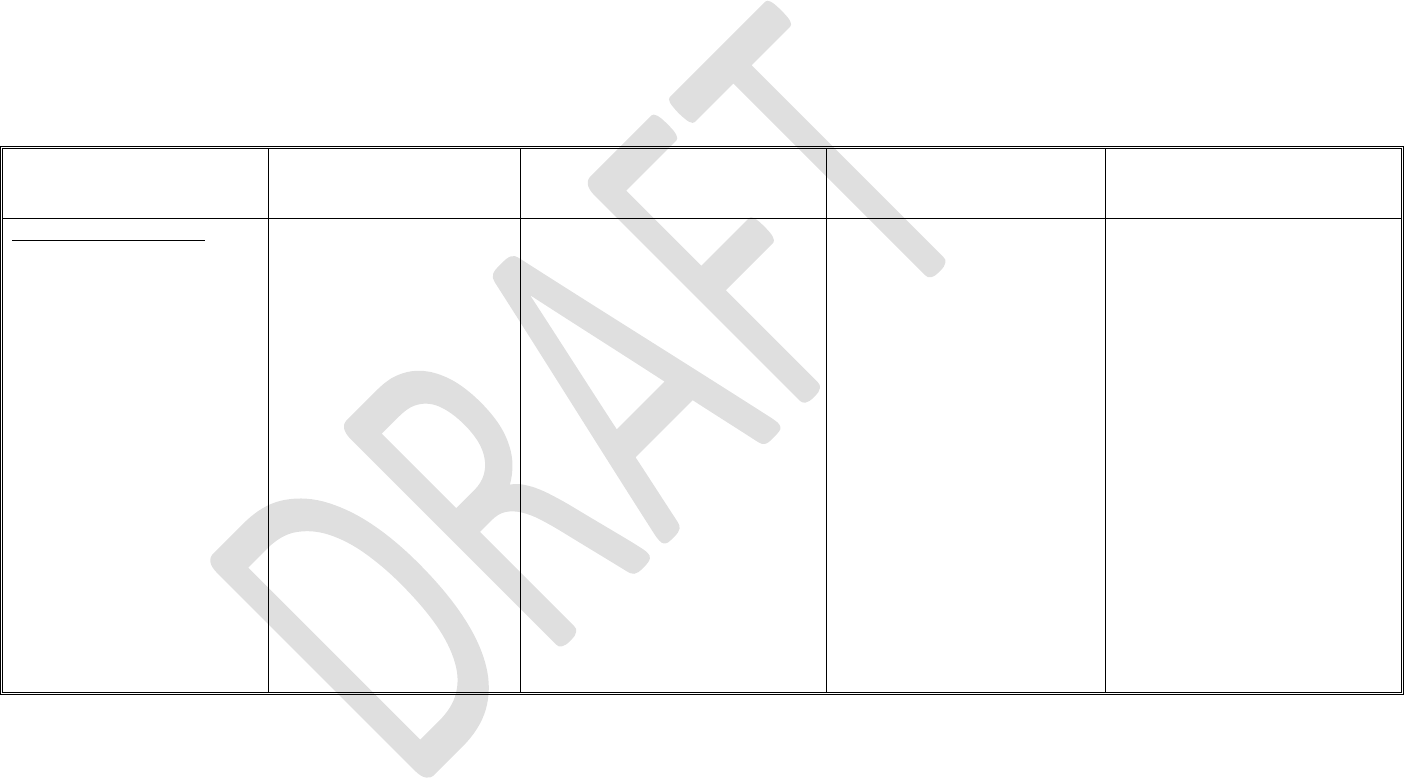

Table 3. Computer Software Assurance Example for an LMS622

Features, Functions, or Operations

Intended Use of the Features,

Functions or Operations

Risk-Based Analysis

Assurance Activities

Establishing the

appropriate record

· The system provides user log-on

features (e.g., username and

password)

· The system assigns trainings to users

per the curriculum assigned by

management

· The system captures evidence of

users’ training completion

· The system notifies users of training

curriculum assignments, completion

of trainings, and outstanding

trainings

· The system notifies users’

management of outstanding trainings

· The system generates reports on

training curriculum assignments,

completion of training, and

outstanding trainings

All of the features, functions,

and operations have the same

intended use, that is, to manage,

record, track and report on

training. They are intended to

automate processes to comply

with 21 CFR 820.25

(Personnel), and to establish the

necessary records.

Failure of these features,

functions, or operations to

perform as intended would

impact the integrity of the

quality system record but

would not foreseeably

compromise safety. As such,

the manufacturer determined

that the features, functions,

and operations do not pose

high process risk.

The manufacturer has

performed an assessment

of the system capability,

supplier evaluation, and

installation activities. In

addition, the manufacturer

supplements these

activities with unscripted

testing, applying error-

guessing to attempt to

circumvent process flow

and “break” the system

(e.g. try to delete the audit

trail).

The manufacturer

documents:

· the intended use

· risk determination

· a summary description

of the failure modes

tested

· any issues found and

their disposition

· a concluding statement

noting that the

performance of the

operation is acceptable

· the date testing was

performed, and who

performed the testing.

623

624

Contains Nonbinding Recommendations

Draft – Not for Implementation

24

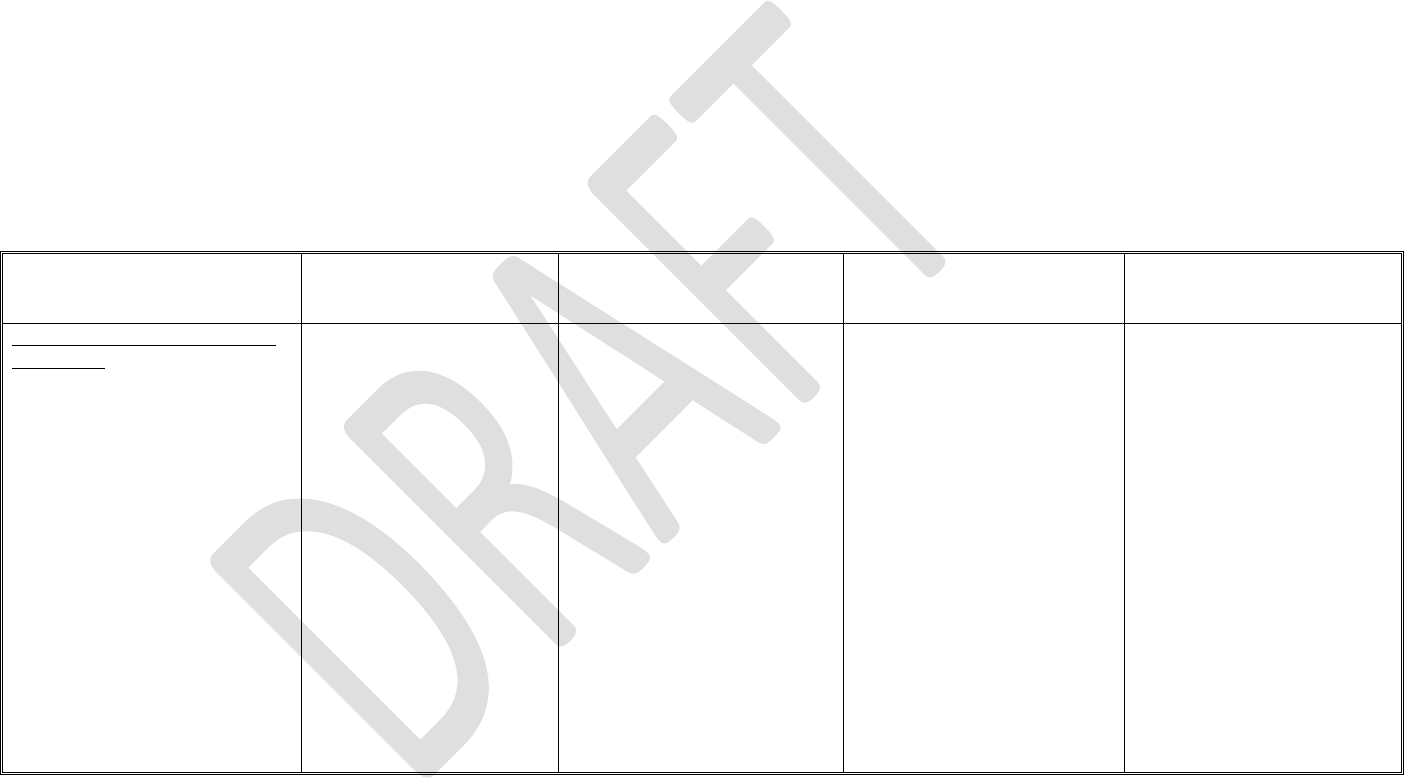

Example3:BusinessIntelligenceApplications625

A medical device manufacturer has decided to implement a commercial business intelligence solution for data mining, trending, and 626

reporting. The software is intended to better understand product and process performance over time, in order to provide identification 627

of improvement opportunities. The following features, functions, or operations were considered by the manufacturer in developing a 628

risk-based assurance strategy: 629

630

Table 4. Computer Software Assurance Example for a Business Intelligence Application631

Features, Functions, or

Operations

Intended Use of the

Features, Functions or

Operations

Risk-Based Analysis

Assurance Activities

Establishing the appropriate

record

Connectivity Functions:

· The software allows for

connecting to various

databases in the

organization and external

data sources.

· The software maintains

the integrity of the data

from the original sources

and is able to determine if

there is an issue with the

integrity of the data,

corruption, or problems

in data transfer.

These functions are

intended to ensure a secure

and robust capability for the

system to connect to the

appropriate data sources,

ensure integrity of the data,

prevent data corruption,

modify, and store the data

appropriately.

Failure of these functions to

perform as intended would result

in inaccurate or inconsistent

trending or analysis. This would

result in failure to identify

potential quality trends, issues or

opportunities for improvement,

which in some cases, may result in

a quality problem that foreseeably

compromises safety. As such, the

manufacturer determined that these

functions posed high process risk,

necessitating more-rigorous

assurance activities, commensurate

with the related medical device

risk.

The manufacturer determined

assurance activities

commensurate with the medical

device risk and has performed

an assessment of the system

capability, supplier evaluation,

and installation activities.

Additionally, the manufacturer

establishes a detailed scripted

test protocol that exercises the

possible interactions and

potential ways the functions

could fail. The testing also

includes appropriate

repeatability testing in various

scenarios to provide assurance

that the functions work reliably.

The manufacturer documents:

· the intended use

· risk determination

· detailed test protocol

· a detailed report of the testing

performed

· pass/fail results for each test

case

· any issues found and their

disposition

· a concluding statement

noting that the performance

of the operation is acceptable

· the date testing was

performed, and who

performed the testing

· the signature and date of the

appropriate signatory

authority.

Contains Nonbinding Recommendations

Draft – Not for Implementation

25

Features, Functions, or

Operations

Intended Use of the

Features, Functions or

Operations

Risk-Based Analysis

Assurance Activities

Establishing the appropriate

record

Usability Feature:

· The software provides the

user a help menu for the

application.

This feature is intended to

facilitate the interaction of

the user with the system and

provide assistance on use of

all the system features.

The failure of the feature to

perform as intended is unlikely to

result in a quality problem that

would lead to compromised safety.

Therefore, the manufacturer

determined that the feature does

not pose high process risk.

The feature does not necessitate

any additional assurance effort

beyond what the manufacturer

has already performed in

assessing the system capability,

supplier evaluation, and

installation activities.

The manufacturer documents:

· the intended use

· risk determination

· the date of assessment and

who performed the

assessment

· a concluding statement

noting that the performance

is acceptable given the

intended use and risk.

Reporting Functions:

· The software is able to

create and perform

queries and join data

from various sources to

perform data mining.

· The software allows for

various statistical analysis

and data summarization.

· The software is able to

create graphs from the

data.

· The software provides the

capability to generate

reports of the analysis.

These functions are

intended to allow the user to

query the data sources, join

data from various sources,

perform analysis, and

generate visuals and

summaries. These functions

are intended for collection

and recording data for

monitoring and review

purposes that do not have a

direct impact on production

or process performance. In

this example, the software is

not intended to inform

quality decisions.

Failure of these functions to

perform as intended may result in a

quality problem (e.g., incomplete

or inadequate reports) but, in this

example, would not foreseeably

lead to compromised safety

because these functions are

intended for collection and

recording data for monitoring and